Project Description

- Compact design with rugged construction

- Capable of withstanding high pressure

- O-ring is dynamically loaded to prevent shaft damage

- Can handle media with solid content

and viscous media - Can handle sterile and vacuum application

- Springs are product protected to avoid contamination

- Conveying and bottling of dairy products

- Dirty, abrasive and solids containing media

- Pulp and paper industry

- Sugar industry

- Water and waste water technology

- Raw sludge pumps

- Raw sludge, sewage slurries

- Thick juice pumps

- EN 12756

- Variant for sterile applications available.

- Please enquire.

- Seal face: Carbon graphite antimony

impregnated (A), - Carbon graphite resin impregnated (B)

- Seat G16: Silicon carbide (Q1)

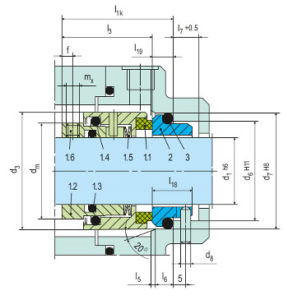

- Sizes: d1 = Upto 100 mm (Upto 4.000’’)

- Pressure: p1*) = 0.8 abs… 25 bar

(12 abs…. 363 PSI) - Temperature: t = -50 °C…+220 °C

(-58 °F…+430 °F) - Speed = 20 m/s (66 ft/s)

- Permissible axial movement: ±0.5 mm

*) An integral stationary seat lock is not needed

within the permissible low pressure range. For

prolonged operation under vacuum it is

necessary to arrange for quenching on the

atmospheric side.

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- For plain shafts

- Rotary unit with encapsulated spring

design