Project Description

- Construction design for operating

pressure up to 200 bar - Hassle free maintenance is achieved in

operation with high reliability, because

the dirt is automatically conveyed to the

suction nozzle of the pump - High filtration efficiency

- Compact design is achieved because

of low space requirement, in addition to

the option of block-type design with

integrated flange connections - Design allows for varied applications

due to construction in stainless steel

with replaceable insert made of ceramic

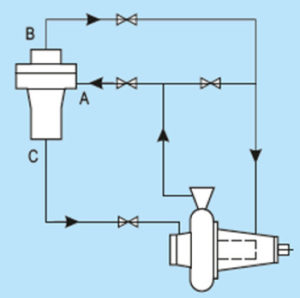

- The cyclone separator must always be installed in the

vertical position. The pressure at the outlets (C) and (B)

must be lower than at the inlet (A). Cleaned liquid is

conveyed to the top (B) and the separated dirt to the

suction port of the pump.

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- Water and waste water technology

- Circulation in accordance with API 682 /

ISO 21049: Plan 31, Plan 41 - The CS range is available in varied

versions i.e. cyclone separator with

replaceable insert made of ceramic or cast

version of the cyclone separator or

cyclone separator for high flow rates and

high pressures.