Project Description

CGT3111 – THERMOSIPHON SYSTEMS

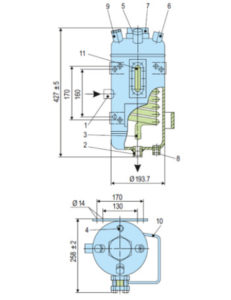

| Item No. | Description |

|---|---|

| 1 | Buffer/barrier fluid IN (G1/2″) |

| 2 | Buffer/Barrier fluid OUT (G1/2″) |

| 3 | Cooling water IN (G1/2″) |

| 4 | Cooling water OUT (G1/2″) |

| 5 | Filling connection with plug (G1/2″) |

| 6 | Pressure gas connection (G1/2″) |

| 7 | Connection for level switch or level indicator (G2″) |

| 8 | Connection for hand refill pump (G1/2″) |

| 9 | Universal connection (G1/2″) for safety valve, flare,etc |

| 10 | Bracket for hand refill pump |

| 11 | Sight-glass |

- Available with or without cooling coil

- Optimum draining and venting is

achieved because of the design of

cooling water connections at top (OUT)

and bottom (IN) - Sockets are designed with recessed

gasket to avoid contamination of the

circuit by thread sealant - Construction of the BFS 2000 is

designed for demanding operating

conditions up to 30 bar / 200°C - Design allows for varied applications

due to construction in stainless steel

with borosilicate sight-glasses

- The BFS system performs all the basic functions of a buffer/barrier system for the operation of double seals:

- To pressurize the buffer chamber

- Leakage compensation

- Buffer/barrier fluid is circulated by

thermosiphon effect or external circulation system - To cool the seal

- To selectively absorb product leakage and

prevent dry running (tandem arrangement) - Use compressed air or nitrogen for pressurization

- The BFS vessel must always be installed higher

than the mechanical seal. The buffer/barrier fluid

flows via the return pipe into the vessel and is

cooled. The exchange of fluid takes place by the

thermosiphon principle or by forced circulation,

e.g. with a pumping screw. Connection pipes to

the seal should be designed with as little

resistance as possible. - Measuring unit

- Level Switch

- From PCV, we recommend using a reverse

controlled pressure control valve (PCV) - Hand Refill Pump

- Circulating Pump

- Mechanical seal

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- PED 2014/68/EU (Design and production in

accordance with EU Pressure Equipment Directive) - ASME VIII, Div.1 (Design, calculation and production)

- BFS 2000 system is employed for

applications in sealing systems with a wide

variety of operating parameters for supplying

buffer/barrier fluid to double and tandem

mechanical seals. The BFS 2000 system is

available in standard sizes with flat ends,

sight-glasses for level monitoring and with or

without cooling coil. BFS 2000 system is

equipped as a standard with all the necessary

system connections and brackets. Modular

design combination available with a wide

variety of system components and

instruments selection possible such as, level

switch, circulation pump, hand refill pump,

thermometer, base frame etc. - Circulation in accordance with API 682 / ISO

21049: Plan 52, Plan 53A