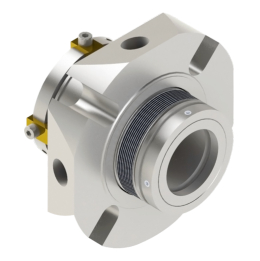

Project Description

- Ideal for use in process pump

standardization - Dimensional modification of the stuffing

box chamber is not required due to

short radial installation height - Ideal to convert and retrofit pumps with

packings and large volume OEM

production - Cartridge unit factory assembled for

easy installation, which reduces downtime - Rugged design for long operating life

- Bellows design efficiently ensure selfcleaning

- Suitable for high temperature

applications

- Refining technology

- Petrochemical industry

- Hot media

- Cold media

- Highly viscous media

- Pumps

- Special rotating equipment

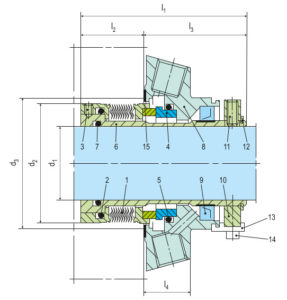

- Seal face: Carbon graphite antimony

impregnated (A), Silicon carbide (Q1) - Seat: Silicon carbide (Q1)

- Secondary seals: FKM (V), EPDM (E), FFKM (K)

- Bellows: Inconel® 718 (M6)

- Metal parts: CrNiMo steel (G), Duplex (G1)

- Throttle ring: PTFE carbon graphite reinforced (T12)

- Lip seal: NBR (P), PTFE carbon reinforced (T3)

- Shaft diameter: d1 = 25 … 80 mm (1″ … 3.15″)

- Temperature:

t* = -40 °C … +220 °C (-40 °F … +428 °F) - Pressure: p = 25 bar (363 PSI)

- * Operating limits of O-Rings to be observed

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge construction

- Metal bellows design

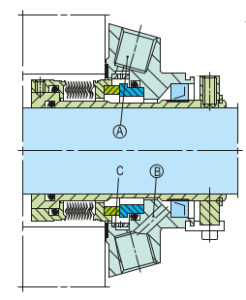

- Single seal with quench and lip seal

(-QN) or throttle ring (-TN) - Connections for flush and quench

available - Multipoint injection ring design for

(-QNM, -TNM)