Project Description

- Accommodates shaft deflections due to

stationary design - Can be designed for individual pump

application with corresponding

connection parts to be adopted to the

pump seal chamber - Optimum heat dissipation due to

integrated pumping device available for

increased efficiency in circulation and

optimized seat design - Cartridge unit factory assembled for

easy installation, which reduces downtime - Trouble-free long-term operation due to

heavy duty single seat design with

bandage - Can operate under high sliding

velocities and high pressures

- Amines

- Caustic soda

- Chemical industry

- Crude oil

- Crystallizing media

- Crude oil feed pumps

- Hot water

- Injection pumps

- Multi-phase pumps

- Oil and gas industry

- Process water

- Refining technology

- Sour water

- API 682 / ISO 21049

- Seal face: SiC-C-Si silicon impregnated carbon (Q3), Carbon graphite antimony

impregnated (A) - Seat: Silicon carbide (Q)

- Secondary seals: FKM (V), EPDM (E),

FFKM (K) - Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), Duplex (G1),

Super Duplex (G4), Titanium (T2),

Hastelloy® C-4 (M)

- Sizes: d1* = Upto 250 mm (Upto 10.000’’)

- Pressure: p1 = 150 bar (2,175 PSI)

- Temperature: t = 300 °C (572 °F)

- Speed = 60 m/s (197 ft/s)

- Permissible axial movement: ± 3 mm

*Other sizes on request

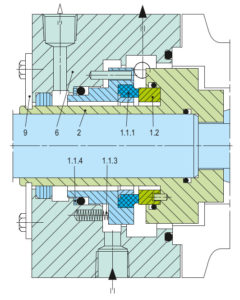

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge construction

- Stationary design with multiple springs

- Designed with integrated pumping

device for increased efficiency in

circulation - Robust construction with shrink-fitted

seal face - Heavy duty design of solid stationary seat