Project Description

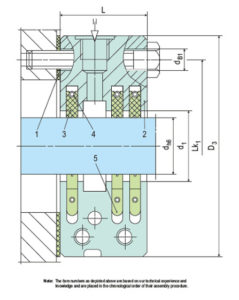

- Ease of installation during assembly

due to split design (dismantling of shaft

is not necessary) - Operational durability

- Easy to maintain

- Trouble free replacement due to

segmented seal ring design

- Bearing seals (gear box, motors)

- Chemical industry

- Food processing industry

- Fumes and exhaust,solids containing, flammable (ATEX), acid containing and toxic gases (Solids containing) steams / liquid mist Gases

- Medium-sized and large fans / blowers

- Metal production and processing

- Mixers, agitators, mills, dryer

- Oil mist / penetrating oil

- Petrochemical industry

- Power plant technology

- Steam turbines

- Waste incineration and removal industry

- Water

- FDA

- Seal ring: Carbon, PTFE compound

- Housing: 1.4021, 1.4571, Hastelloy®, Titanium,

- Inconel®, others

- Tension spring / detent: 1.4571, Hastelloy®,

- Titanium, Inconel®

- Shaft diameter:

d = 40 … 340 mm (1.57″ … 13.39″) - Operating pressure:

p = vacuum … 20 bar (290 PSI) abs. - Operating temperature: t = -120 °C … +800 °C

(-184 °F … +1,472 °F) for carbon,

max. 225 °C (437 °F) for PTFE compound - Speed = max. 150 m/s (492 ft/s) for carbon, max. 40 m/s (131 ft/s)for PTFE compound

- Radial play: ±1.0 … 5.0 mm (±0.04″ … 0.2″)

- Axial movement: theoretically unlimited

- Recommended wear guard: >300 HB (low

pressure), >58 HRC (high pressure)

- Designed to accommodate axial shaft

movement - Capable of running dry

- Radially cut multi-part seal rings

- Shaft free of sealing components which

minimizes the shaft vibrations - Seal rings are self adjusting

- Shaft movement is accommodated by

seal rings - Minimal power consumption as seal

rings are non-contacting - Design of the seal housing is split

- Low leakage due to extremely reduced

gap during operation