Project Description

- Cooling capacity up to 10.5kW

- Cost effective solution

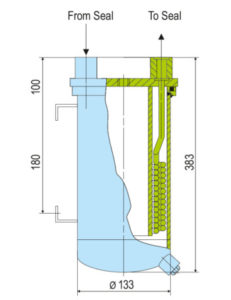

- Effective cooling achieved with wound

double helix around a guide tube - Designed for varied applications due

to construction in stainless steel - For optimum and simple cleaning, the

heat exchanger can be dismantled

- Chemical industry

- Petrochemical industry

- Power plant technology

- Refining technology

- Oil and gas industry

- PED 2014/68/EU (Design and production in

accordance with EU Pressure Equipment Directive)

- Mount vertically with connections pointing up.

Provide for external venting on the process/barrier

medium side (the user has to install a vent at the

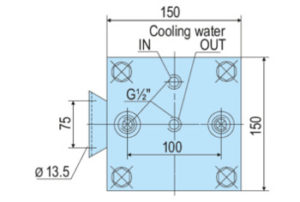

highest point of the pipe work). - Cleaning:

Cooling water side: the area around the tubes can be

cleaned mechanically after the housing is removed. - Process/barrier medium side: flush with a suitable

solvent.

- Circulation in accordance with API 682 /

ISO 21049: Plan 21, Plan 22, Plan 23,

Plan 41 - HEK designed heat exchanger is

employed to cool process/barrier fluids in

seal supply systems. The heat exchanger

has a wound double helix around the

guide tube, the process/barrier medium is

directed through the shell of the HEK and

the cooling medium through the tubes