Project Description

- Versatile torque transmission available

- Pumping screw for media with higher

viscosity also available - Capable of self-cleaning

- Short installation length available on

request - Can be employed for low solids content

- Multifaceted application usage

- EN 12756 (For connection dimensions

d1 upto 100 mm)

- Adhesives

- Chemical industry

- Low solids content and low abrasive media

- Media with poor lubrication properties

- Process industry

- Toxic and hazardous media

- Chemical standard pumps

- EN 12756

- Seal face: Special cast CrMo steel (S),

Silicon carbide (Q1, Q2) - Seat G9: Carbon graphite antimony

impregnated (A), Carbon graphite resin

impregnated (B), Silicon carbide (Q1*, Q2*) - Seat G4: Silicon carbide (Q1*, Q2*)

- Seat G6: Silicon carbide (Q1*, Q2*)

- Seat G13: Carbon graphite antimony

impregnated (A), Carbon graphite resin impregnated (B)

* Cannot be combined with seal face made of S

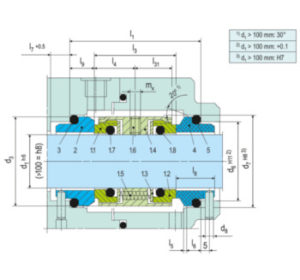

- Sizes: d1 = Upto 200 mm (Upto 7.875’’)

- Pressure: p1 = 25 bar (363 PSI)

- Temperature: t = -50 °C … + 220 °C

(-58 °F … + 428 °F) - Speed = 20 m/s (66 ft /s)

- Permissible axial movement:

d1 upto 100 mm: ± 0.5 mm

d1 from 100 mm: ± 2.0 mm

- Dual seal configuration

- Unbalanced design

- Independent of direction of rotation

- For plain shafts

- Multiple or wave springs rotary

construction - Pumping device available for

increased efficiency in circulation

(U740F-D) - Sealing with FEP & Spring energized

PTFE seals also available on request