Project Description

- Low cost seal solution

- Suitable for mild sterile applications

- No damage to the shaft

- Can be employed for low solids content

- Multifaceted application usage

- Food and beverage industry

- Multi-stage pumps (non-drive side)

- Media with low solids content

- Pressure oils for bio diesel fuels

- Water and waste water technology

- Water and waste water pumps

- Cooling fluids

- Circulating pumps

- Oil applications

- Chemical industry

- Submersible pumps

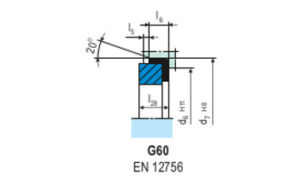

- EN 12756

- FDA

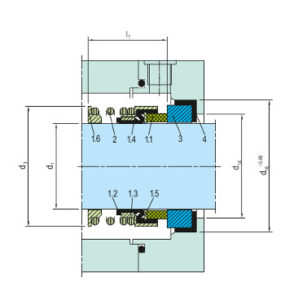

- A modular principle comprising a bellows unit for each shaft diameter and a corresponding cylindrical spring for individual length compensation to l1 installation length. The UG943 can also be used as a multiple seal in tandem or in a back-to-back arrangement. The entire UG943 series is available in metric and inch sizes

- Seal face: Carbon graphite antimony impregnated (A),

Carbon graphite resin impregnated (B),

Silicon carbide (Q1) - Seat: Silicon carbide (Q1 , Q2),

Aluminium oxide (V) - Elastomer: NBR (P), EPDM (E), FKM (V),

HNBR (X4)

Metal parts: CrNiMo steel (G)

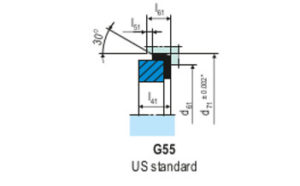

- Shaft diameter: d1 = 10 … 100 mm (0.375″ … 4″)

- Pressure: p1 = 12 bar (174 PSI),

vacuum up to 0.5 bar (7.25 PSI), up to 1 bar (14.5 PSI)

with seat locking - Temperature: t = -20 °C … +140 °C (-4 °F … +284 °F)

- Sliding velocity: V g = 10 m/s (33 ft/s)

- Axial movement: ± 0.5 mm

- Single seal configuration

- Unbalanced design

- Independent of direction of rotation

- For plain shafts

- Rotary elastomer bellows design