Project Description

- Low cost seal solution

- Suitable for mild sterile applications

- No damage to the shaft

- Can be employed for low solids content

- Multifaceted application usage

- Chemical industry

- Food processing industry

- Pulp, paper & Latex

- Water, waste water and mild slurries

- Chemical standard pumps

- Helical screw pumps

- Submersible pumps

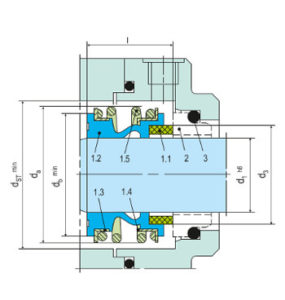

- EN 12756

- The UG100 can also be used as a multiple seal in

tandem or in a back-to-back arrangement. - Installation proposals can be supplied on

request. - Dimension adaptations for specific conditions,

e.g. shaft in inches or special seat dimensions are

available on request.

- Seal face: Carbon graphite antimony

impregnated (A), Carbon graphite resin

impregnated (B), Silicon carbide (Q1),

Tungsten carbide (U3) - Seat: Silicon carbide (Q1, Q2), Tungsten

carbide (U3), Special cast CrMo steel (S),

Aluminium oxide (V) - Elastomer: NBR (P), EPDM (E), FKM (V),

Metal parts: CrNiMo steel (G), Hastelloy®

C-4 (M).

- Sizes: d1 = Up to 100 mm (Up to 4.000’’)

- Pressure: p1 = 16 bar (230 PSI)

- Vacuum: 0.5 bar (7.25 PSI), up to 1 bar (14.5

PSI) with seat locking - Temperature: t = -20°C…+140°C (-4°F…+284°F)

- Speed: = 10 m/s (33 ft/s)

- Permissible axial movement: ±2.0 mm

- Single seal configuration

- Unbalanced design

- Independent of direction of rotation

- For plain shafts

- Rotary elastomer bellows design