Project Description

QCT3111 – PRESSURE BOOSTER SYSTEMS

- Simple and reliable operation is achieved due to

automatic setting of the barrier pressure

through reference pressure - Barrier pressure is achieved without any need

for connection to a nitrogen supply source - Hassle free maintenance of simple and quick

cleaning is achieved in operation as the housing

can be dismantled - Modular design combination available with a

wide variety of system components possible - Optimum level of monitoring is achieved due to

the protective pipe made in borosilicate glass - Safe operation even in case of pressure

changes - Sockets are designed with recessed gasket to

avoid contamination of the circuit by thread

sealant

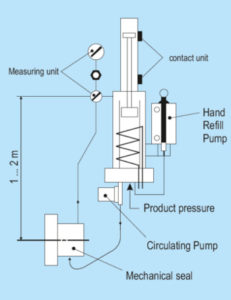

- The function of the PBS system is similar in principle

to the BFS system. The difference is that the

barrier pressure is created by the reference

pressure without any additional superimposition of

nitrogen. The pressure booster is for storing and

cooling the barrier fluid. Pressurization is by means

of a piston in dependency on the process/medium

pressure. Automatic pressure increase in

accordance with the transmission ratio.

- Refining technology

- Oil and gas industry

- Chemical industry

- Petrochemical industry

- PED 2014/68/EU (Design and production in

accordance with EU Pressure Equipment

Directive) - ASME VIII, Div. 1

(Design, calculation and production)

- Circulation in accordance with API 682 / ISO

21049: Plan 53C - PBS system is employed for applications in

sealing systems with a wide variety of

operating parameters for supplying quench

buffer fluid to double and tandem mechanical

seals. PBS system is equipped as a standard

with all the necessary system connections

and brackets. Modular design combination

available with a wide variety of system

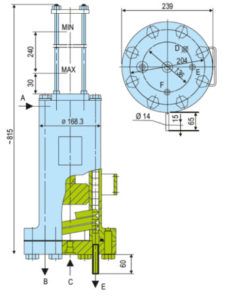

components. - The maximum operating pressure of the PBS

system applies to the housing of the pressure

booster, i.e. the process/medium pressure at

the connection must be lower and is

conditional on the transmission ratio.