Project Description

- Ideal for use in ANSI process pumps

- O-Ring is dynamically loaded to prevent shaft damage

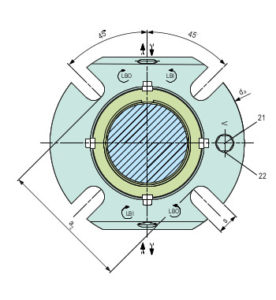

- Dimensional modification of the stuffing box chamber is not required due to short radial installation height

- Ideal to convert and retrofit pumps with packings and large volume OEM production

- Cartridge unit factory assembled for easy installation, which reduces downtime

- Rugged design for long operating life

- ANSI process pumps

- Chemical industry

- Food and beverage industry

- Petrochemical industry

- Pharmaceutical industry

- Universally applicable

- Water and waste water technology

- ANSI

- Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

- Seat: Silicon carbide (Q1)

- Secondary seals: FKM (V), EPDM (E), FFKM (K), Perfluorocarbon rubber/PTFE (U1)

- Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

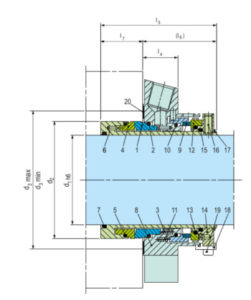

- Sizes: d1 = 1.000″ …. 3.750″

Other sizes on request

Temperature: t= -40 °C … +220 °C (- 40 °F … +428 °F)

(Check O-ring resistance) - Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Speed = 16 m/s (52 ft/s) - Sliding face material combination Q1Q1 or U2Q1

Pressure: p1 = 20 bar (290 PSI)

Speed = 10 m/s (33 ft/s)

Barrier fluid circulation system:

p3max = 25 bar (363 PSI)

Δp (p3 – p1 ) ideal = 2 … 3 bar (29 … 44 PSI),

7 bar (102 PSI) for barrier media with poor lubricating properties)

Pump startup:

Δp (p3 – p1 )max = 25 bar (363 PSI) allowed

Recommended supply medium: max. ISO VG 5

Permissible axial movement: ± 1.0 mm, d1 ≥ 75 mm ± 1.5 mm

- Dual seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge construction

- Available for standard (DUY-ASDN) and big bore (DUY-ABDN) seal chambers

- Double pressure balanced

- Designed with integrated pumping device for increased efficiency in circulation