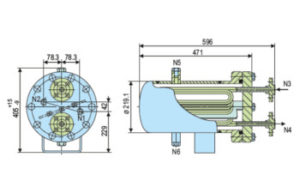

Project Description

- Construction design for operating

pressure up to 45 bar / 260°C (tube

side) - Design allows for varied applications

due to construction in stainless steel - For optimum and simple cleaning of the

tubes, the heat exchanger can be

dismantled - Complete venting and draining of the

cooling water side and process can be

achieved

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- Cleaning:

Cooling water side: the area around the tubes

can be cleaned mechanically after the housing is

removed. - Process/barrier medium side: flush with a suitable solvent.

- Circulation in accordance with API 682 / ISO

21049: Plan 21, Plan 22, Plan 23, Plan 41 - HE designed heat exchanger is used to cool

process/barrier fluids in seal supply systems. - HE heat exchanger is available in standard

construction and conforms to API 682

standards. - The process/barrier medium is directed

through the tube and the cooling medium

through the shell. For simple draining or

venting on the side of the cooling water, the

heat exchanger can also be supplied with

ventilation/drainage ball valves. Temperature

instruments can also be fitted in the supply line

of the mechanical seals.