Project Description

- O-rings are dynamically loaded to prevent shaft damage

- Easy and trouble-free installation

- Due to large radial clearance the damage to the seal faces are avoided, in addition to the seal faces being protected by strong steel parts

- Misalignment during installation and operations is reduced due to the static springs

- Pulp and paper industry

- Chemical industry

- All clean none abrasive media

- Ahlstar UP A MS21 range of pumps

- Sulzer A, APP/APT pumps

- Sulzer SL mixers

- Metso conical refiners

- Stock pumps

- Seal face: Silicon carbide (Q12), Carbon (A)

- Secondary seals: FKM (V), EPDM (E), FFKM (K)

- Metal parts: CrNiMo steel (G),

- Grade 5A (4T), SMO 654 (4U)

- Temperature: t =-20 °C …+140 °C (-4°F …+284 °F)

- Pressure: p1 … 25 bar (363 PSI)

- Sliding velocity: vg … 20 m/s (66 ft/s)

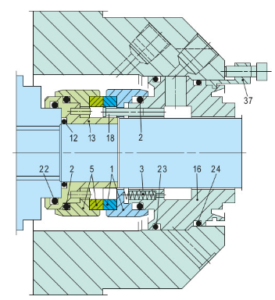

Single seal configuration

Balanced designIndependent of direction of rotation

Semi-Cartridge construction

No dynamic O-Ring on the shaft