Project Description

- Suitable for high temperature

application - Can handle high sliding velocities

- No elastomer secondary seals

- Rugged design for long operating life

- Bellows design efficiently ensure self-

cleaning

- Chemical industry

- High sliding velocities

- Hot media

- Power plant technology

- Refining technology

- Bellows: Inconel® 718 (M6), Hastelloy® C-276 (M5)

- Seal face: Carbon graphite antimony impregnated (A), Silicon carbide (Q12)

- Seat: Silicon carbide (Q1), Special cast

CrMo steel (S) - Metal parts: Duplex (G1), Carpenter® 42

(T4), Hastelloy® C-4 (M)

- Sizes: d1 = Upto 100 mm (Upto 4.000’’)

- Externally pressurized: p1 = 25 bar (363 PSI), (higher

pressure possible, please inquire) - Internally pressurized:

p1 <120 °C (248 °F) 10 bar (145 PSI),

p1 <220 °C (428 °F) 5 bar (72 PSI),

p1 <400 °C (752 °F) 3 bar (44 PSI)

Stationary seat lock necessary. - Temperature: t = -20 °C … +400 °C (-4 °F … +752 °F)

Speed = 50 m/s (165 ft/s)

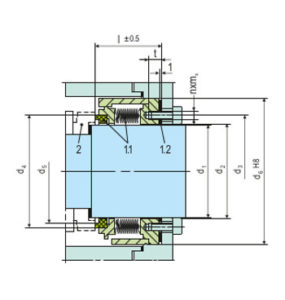

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- Stationary metal bellows design