Project Description

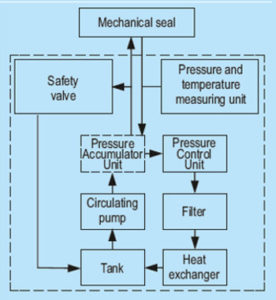

CGT 65 – BUFFER FLUID SYSTEMS

- For reducing barrier fluid pressure at

standstill an automatic relief valve is

provided - Reversible double filter is provided for the

fluid to pass through the oil cooler - Level Switch with contact for minimum level

- Barrier fluid pressure can be controlled

manually - Maximum operating temperature in the tank

to be maintained at 80 oC (return line

maximum 90 oC) - For monitoring the pump discharge pressure

(outside the circuit) an additional pressure

connection is provided - Temperature monitoring is achieved by

providing a return line and tank thermometer

- For reducing barrier fluid pressure at

standstill an automatic relief valve is

provided - Reversible double filter is provided for the

fluid to pass through the oil cooler - Level Switch with contact for minimum level

- Barrier fluid pressure can be controlled

manually - Maximum operating temperature in the tank

to be maintained at 80 oC (return line

maximum 90 oC) - For monitoring the pump discharge pressure

(outside the circuit) an additional pressure

connection is provided - Temperature monitoring is achieved by

providing a return line and tank thermometer

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- BFS range of barrier pressure units are

designed to perform various functions of a

barrier system which is essential for

operating double seals (circulation and

cooling of the barrier medium, pressurisation

of the barrier fluid and compensation of

leakage). The BFS systems are designed to

operate with hydraulic oil having viscosity

values ranging from 12 to 90 mm2/s under

normal operating temperature of the

equipment. The final selection of optimum

viscosity of the oil to be used has to be

ascertained independently in accordance

with the respective operating parameters of

the equipment