Project Description

- Accommodates shaft deflections due to

stationary design - Designed to handle media containing

solids - O-ring is dynamically loaded to prevent

shaft damage. - Can operate under vacuum without

locking the seat - Pumping device available for increased

efficiency in circulation - Springs are product protected to avoid

contamination

- Water and waste water technology

- Dirty, abrasive and solids containing media

- Dredger pumps

- Mining industry

- Oil and gas industry

- Oil sand extraction plants

- Power plant technology

- Pulp and paper industry

- Sewage water pumps

- Scrubbers in FGD plants

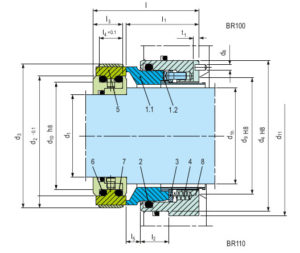

- EN 12756

- Direction of installation:

- From the impeller side: CS100

- From the bearing side: CS110

- Seal face: Silicon carbide (Q1, Q2)

- Seat: Silicon carbide (Q1, Q2)

- Sizes: dN = Upto 270 mm (Upto 10.625’’)

- Pressure: p1 *) = 16 bar (230 PSI)

- Temperature: t = -20 °C …+160 °C

(-4 °F …+320 °F) - Speed = 10 m/s (33 ft/s)

*) For operation under vacuum it is necessary

to arrange for quenching on the atmosphere

side.

- Single and Dual seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge construction

- Stationary design with multiple springs

- Seat arrangement is designed behind

the impeller - Seat design is rotary

- Specially designed sleeve to protect the

springs from contamination - Variable designs available with guide sleeve for applications with or without

quench