Project Description

IFE- HEAT EXCHANGERS

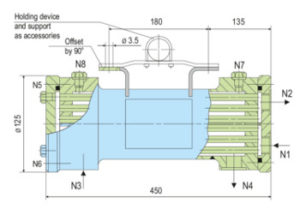

| Item No. | Description |

|---|---|

| N1 | Cooling water IN |

| N2 | Cooling water OUT |

| N3 | Process/barrier medium IN |

| N4 | Process/barrier medium OUT |

| N5 | Cooling circuit vent |

| N6 | Cooling water drain |

| N7/N8 | Process/barrier circuit vent |

- Cooling capacity up to 36 kW

- Installation can be done either in a

vertical or a horizontal position - For optimum and simple cleaning, the

heat exchanger can be dismantled - Compact design of tubular heat

exchanger with integrated guide

plates alongwith extremely efficient

cooling capacity - Designed for varied applications due

to construction in stainless steel

allows flush with a suitable solvent on

the process/barrier medium side

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Power plant technology

- Refining technology

- PED 2014/68/EU (Design and production in

accordance with EU Pressure Equipment

Directive)

ASME VIII, Div. 1 (Design, calculation and

production)

- Cleaning:

- Cooling water side: the area around the tubes can

be cleaned mechanically after the housing is

removed. - Process/barrier medium side: flush with a suitable

solvent.

- Circulation in accordance with API 682 /

ISO 21049: Plan 21, Plan 22, Plan 23,

Plan 41 - HED designed heat exchanger is

employed to cool process/barrier fluids in

seal supply systems. - Construction of the vessel is in a tubular

design with integrated guide plates, the

process/barrier medium is directed

through the shell of the HED and the

cooling medium through the tubes.