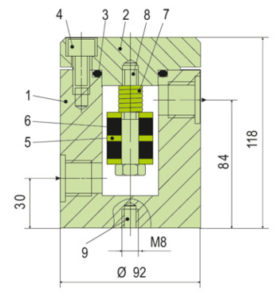

Project Description

- Construction design for operating

pressure up to 150 bar - Hassle free maintenance of simple

and quick cleaning is achieved in

operation as the housing can be

dismantled - Reliability in operation due to rugged

technology

- The magnetic rod is positioned in the casing in

such a way that it catches magnetic particles

flowing past in the medium on all sides.

- Cleaning:

The magnetic rod can be removed for cleaning

with the casing fitted by opening the cover (with

the line depressurized!).

Maintenance intervals depend on the degree of

soiling. We recommend checking and if

necessary cleaning the magnetic rod several

hours after using for the first time and each time

after flushing the pipes because experience

indicates that much of the dirt is flushed out of the

pipes at this time.

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Power plant technology

- Refining technology

- MS range of separators consists of a

pressure casing with integrated magnetic

rod for high level of efficiency. MF filters

are employed in seal supply systems and

any other such systems in which the

media has to be cleaned of magnetic

impurities up to a certain size