Project Description

- Designed for “Low-Emission” conforming to the American STLE-

limits - Can handle extensive applications in

various temperatures and pressures - Versatile in design to fit various seal

chambers - Material of construction available in

special metallurgy

- Light hydrocarbons

- Oil and gas industry

- Petrochemical industry

- Refining technology

- API 610 / ISO 13709 pumps

- Process pumps

- API 682 / ISO 21049

- Seal face: Carbon graphite antimony impregnated (A)

- Seat: Silicon carbide (Q1, Q2)

- Secondary seals: EPDM (E), NBR (P), FKM

(V), FFKM (K) - Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), Duplex (G1), Hastelloy® C-4 (M)

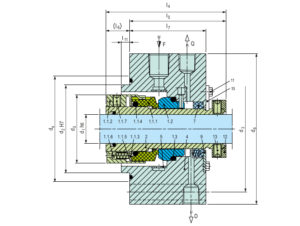

- Sizes: d = Upto 110 mm (Upto 4.250’’)*

- Pressure: p1 = 40 bar (580 PSI)

- Temperature: t = -40 °C … +220 °C (-40 °F…+428 °F)

- Speed = 23 m/s (75 ft/s)

- Permissible axial movement: ± 2.0 … 4.0 mm

depending on diameter and installation situation - * Other sizes on request

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge construction

- Category 2 and 3, Type A, Arrangement

1 - Design in accordance to API 682 / ISO

21049 - Pumping device available for increased

efficiency in circulation (C861WO) - Rotary unit with multiple springs