Project Description

- Seal faces are designed to be noncontacting

during operation - Designed for environmental protection

with high efficiency - Due to non-contacting design there is

no friction on the seal faces and there is

no heat generated at the seal or in the

medium - Trouble free operations as complex

components are not required to

dissipate frictional heat

- Chemical industry

- Refining technology

- Gases and liquids

- Media which require high purity

- Environmental harmful media

- Pumps

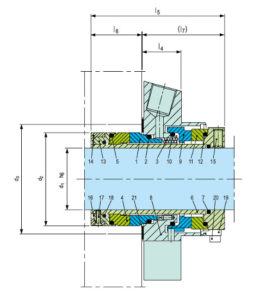

- Seal face: Silicon carbide (Q1/Q19)

- Seat: Silicon carbide (Q19/Q1)

- Secondary seals: FKM (V), EPDM (E), FFKM (K)

- Spring: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), Hastelloy® C-4 (M)

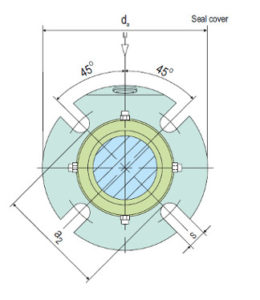

- Shaft diameter:

d1 = 30 … 100 mm (1.18″ … 3.94″) - Pressure:

p1 = 13 bar (189 PSI),

p3 = 16 bar (232 PSI)

with V-grooves (uni-directional)

p1 = 9 bar (131 PSI),

p3 = 12 bar (174 PSI)

with U-grooves (bi-directional)

Differential pressure (p – p ) = min. 3 bar (44 PSI) - Operating temperature limits for:

EPDM -20 °C … +140 °C (-4 °F … +284 °F)

FFKM – 20 °C … +120 °C (-4 °F … +248 °F)

FKM -20 °C … +170 °C (-4 °F … +338 °F)Speed = 4 … 15 m/s (13 … 49 ft/s)

Axial movement: ± 1.0 mm

- Dual seal configuration

- Balanced design

- Cartridge construction

- Stationary design with multiple springs

- Seat design is rotary

- Designed to remain in closed position in

the event of buffer pressure failure - Can accommodate reverse pressure

- Gas-lubricated design

- Gas grooves design is available in Vgrooves

and U-grooves (independent

of direction of rotation)